Capabilities

Brigitflex is a small women owned circuit board shop that’s uses its 40 years of hands on experience in the industry to manufacture all types of circuit boards, from the simple, to the conceptual, we will try almost anything. Brigitflex has a unique ability in understanding the processes involved in creating large format circuit boards on a wide variety of materials. Much of what we do includes antennas, RF/Microwave filters, and R-cards.

Printed Circuit Boards

- Antennas

- RF/Microwave

- R-Cards

- Polarizers

- EM Absorbers

- Embedded Resistors (Ohmega and Ticer)

- Single Sided

- Double Sided

- Multilayer (Any Layer count)

- Flex / Rigid Flex

- High Speed Multilayer

- Aluminum

- Active Cavity

- Passive Embedded Components

- Rigid Air Filter

Materials

- Standard Fr4 (Low and High Temp)

- Polyimides

- Teflon

- Ceramic

- Glass

- Plastics

- Suppliers used but not limited to:

- Rogers

- Taconic

- Arlon

- Isola

- Panasonic

- Nelco

- Ventec

- DuPont

- Ticer

- Ohmega

Large Format Circuit Boards

- Rigid or Flex

- Size options:

- 60″ x 66″

- 48″ x 108″

- 18″ x 180″

- Call for inquires on larger sizes

In House Lamination

- Multiple Electric Heated Presses

- Sizes up to 24″ x 41″

- Fusion Bonding

- Resistor Foil Lamination (Ohmega and Ticer)

- Resistor foil lamination to any Rogers Material

- Sequential Lamination

- Custom Laminations

Drilling

- Blind and Buried Vias

- Slots

- Conductive and Nonconductive Filled

- Drill sizes down to 0.006″

Etching

- Ammoniacal etching

- Ferric chloride etching of many types of metals

Platting

- Copper Platting

- Edge Platting

- Platting Copper to Stainless Steel up to 18″ x 180″

Final Finishes

- Immersion Silver

- Immersion Tin

- ENIG (out of house)

Printed Circuit Board

If you notice the absence of pictures of printed circuit boards we value our customers privacy due to the sensitive nature and complex work we protect all with NDA and PIA agreements.

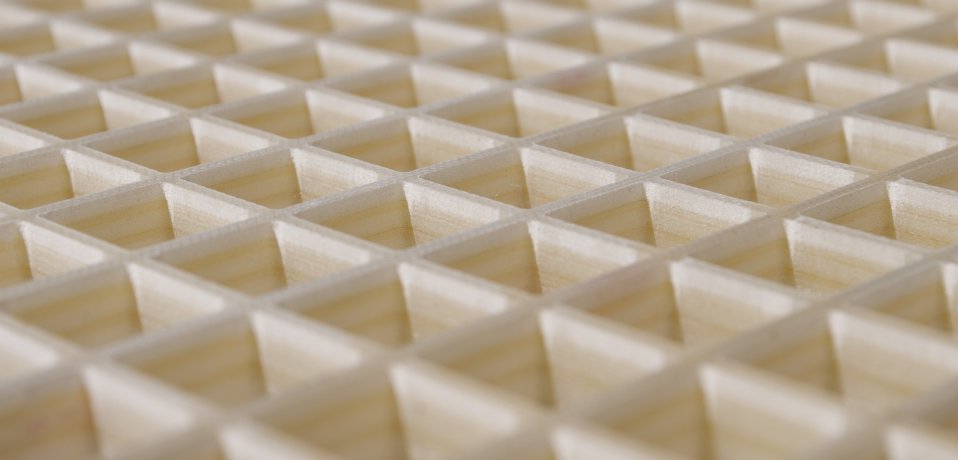

Air Dielectric Printed Circuit Boards

Fabricatin method based on principles of suspended substrated transmission lines between two thin dielectric layers suspended in air conductive planes.

Cavity Antenna Printed Circuit Boards

Embedded and Passive components encapsulated within layers of multilayer printed circuit boards.

Multi Sequential Lamination

Lamination of material cycles multiple times with different drill cycles and press cycles.

Fusion Bonding

Raising a lamination press to approximately 650-700degreeFahrenhart , the PTFE Teflon materials directly bond at the molecular level encapsulating the internal traces for maximizing performance.

Embedded Resistors

Planar resistors that are fabricated inside or on top of a printed circuit board and used as an alternative to discrete resistors.

Mixed Dielectrics

Dielectrics are materials having different mechanical, stress and combination of materials. Registration and pressing need to be coupled to achieve this type of circuit board.

Conductive Via Fill

Conductive paste such has silver and copper used to fill via holes related to double sided and multi layer boards.

Plasma

Use of a Plasma system for printed circuit boards desmear,etchback and surface activation to increase yield and reliability in PTFE Teflon kapton boards.

Filter Boards

Hollow a layer in a multilayer then drop the mfg filter PC Bd into the area adjacent to the ground and signal layers.

Carbon Tetra Fluora

Methane and Oxygen etchback in the through holes and surface copper