New materials appearing daily

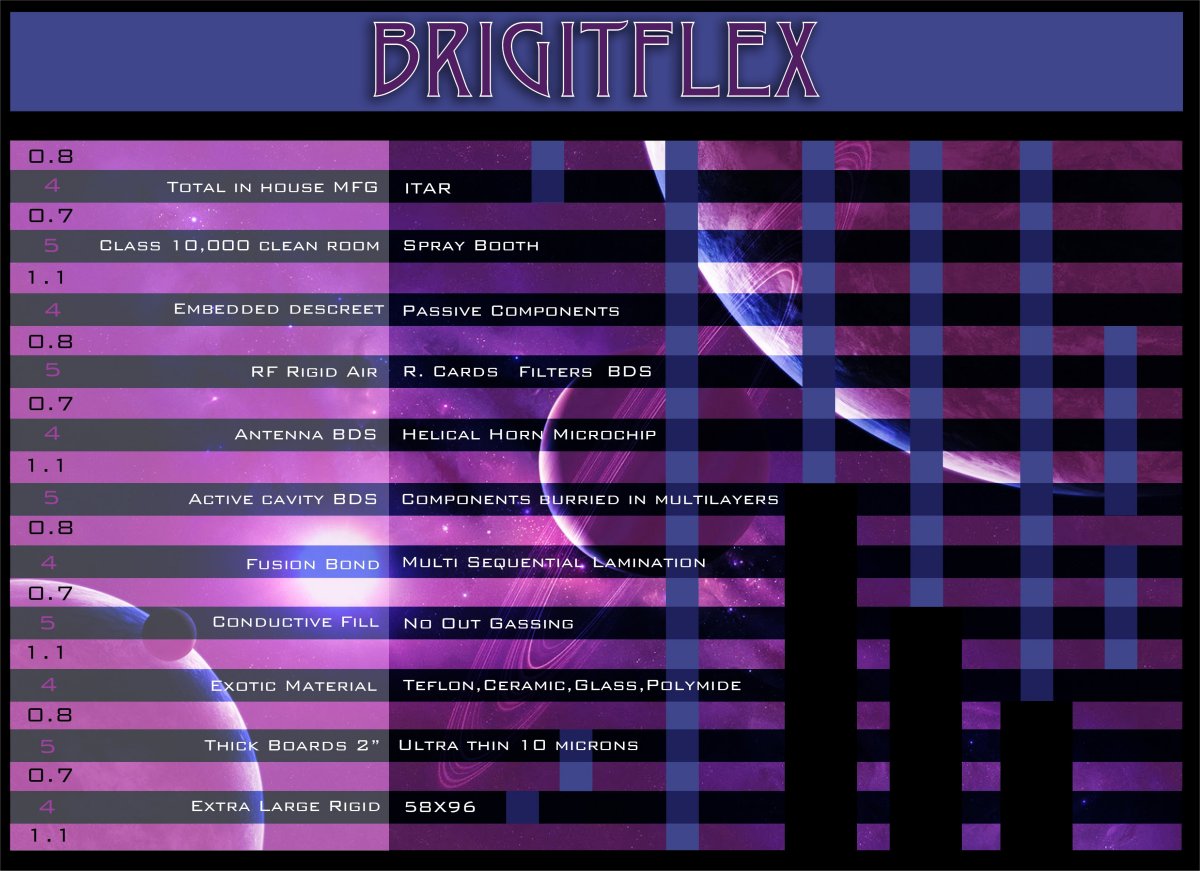

We will experiment to achieve results needed with materials. Some development projects done include pattern-plating on 3-Dimensional surfaces, thickness down to 10 microns, huge multi-dielectrics very heavy copper .062 inner and one inch thick boards. We are asked to make special light weight air dielectric boards or special cavity pressing process with sequential lamination using active and passive components. Materials including RF, LowLoss, DK, HighSpeed, Foam, Teflon, Kapton, Pyrex & BoraSilca Glass, Thin Film, LCP to name a few.

Engineering Formats

Gerber (RS-2740) Extended (RS-274X), DXF/PDF – for other formats contact us.

Clean Room/Spray Booth

Class 10,000 clean room, spray booth, oversized tables at 96×59. Single – double size large antenna bds. We have oversized equipment to handle, carry and move large panels.

Drilling/Fabrication

Driller/Router, Magnaflux x-ray system, Beveling and Scoring capabilities. Plasma etch/de-smear unit.

Multilayer and Pressing

Large vacuum press, 6 openings 24×36, Fusion press, large 6 opening Wabash press at 24×32.

Wet Process

Electrolless, Electoplating, Black Oxide alternative oxide, 60″ etcher/developer.

Screening Deptartment

Blue M ovens, epoxy solder masks – all colors, machined solder mask, dry film, liquid photoimageable.

Machine Shop

Full machine shop including welding equipment.

Lab

EnviroPure Ion Exchange System, Full-time IEPA Class K Licensed Operator, Cross section equipment.